What makes a valve a “severe service” valve?

A valve is typically classified as severe service when it operates in conditions that exceed what standard isolation or control valves are built to handle over time. This usually involves a combination of high pressure, high temperature, aggressive media, high cycle rates, or all of the above at once.

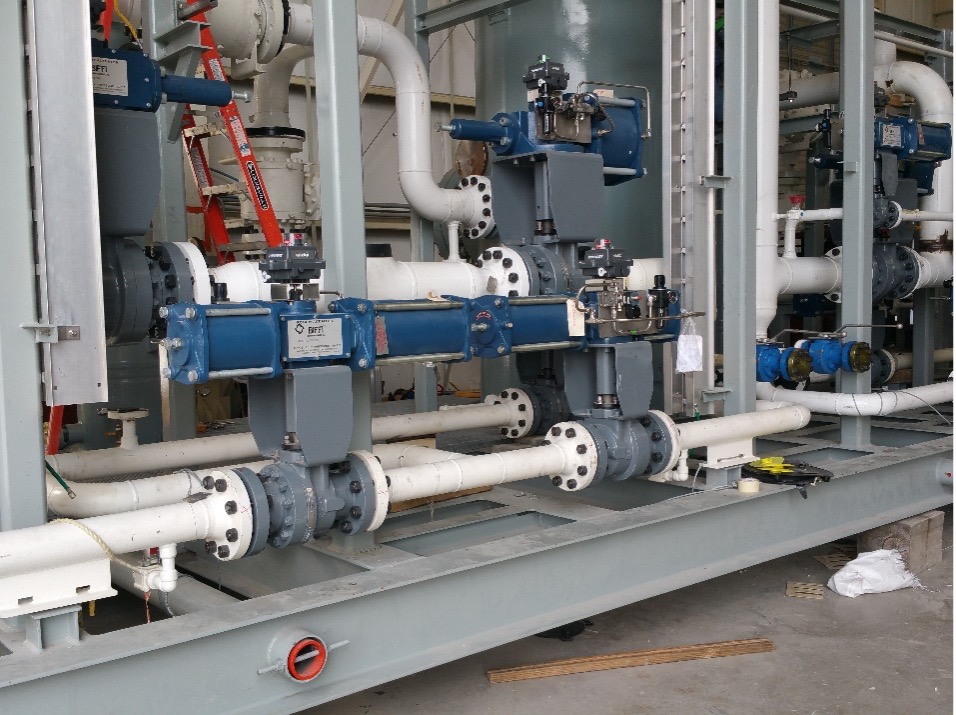

Severe service valves are expected to isolate or control flow under sustained extreme conditions. This includes repeated cycling, thermal swings, and exposure to erosive or corrosive process media. A severe service isolation valve may cycle tens of thousands of times per year, while control applications may see rapid throttling under high differential pressure that can accelerate trim wear.

Typical operating conditions include:

- Pressures exceeding 1,000 psi (ranges vary by industry and media)

- Temperatures above 800°F (ranges vary by industry and media)

- Slurry or catalyst-laden media

- Strong acids or flammable gases

- Fast open-close cycles driven by automated controls

In the field, this shows up as stable torque curves, consistent shutoff performance, and predictable maintenance intervals.

How Severe Service Valve Design Differs from Standard Valves

Zero-leakage shutoff is the baseline expectation. In severe service valves, minor leakage is not minor for long. It usually progresses to seat damage or downstream erosion.

Seat Design, Material Selection

Metal-seated designs are common due to temperature limits and erosion resistance. Soft seats may perform initially but tend to degrade rapidly when exposed to heat, solids, or pressure cycling. Seat geometry and surface finish play a large role in conjunction with materials selections.

Trim, Coatings, Wear Surfaces

Trim and body materials are selected for wear resistance and compatibility with process chemistry. Hardened alloys, tungsten carbide coatings, and specialized surface treatments are often used on seating surfaces. Body materials must handle both pressure and thermal expansion without distortion.

Adjustable And Robust Stem Packing

Since a stem packing leak is direct to atmosphere, leak-free stem packing material is selected based on emissions requirements. Wire mesh reinforcement is often used. The packing gland is adjustable to allow operators to compensate for wear and compression of packing over time

Actuator Sizing, Torque Margin Over Time

Actuator sizing is frequently underestimated. Torque requirements increase over time as seats wear and deposits build up. A common field rule is to size actuators with at least 25 – 30% margin over calculated break torque in severe service isolation duty. When torque margin is insufficient, the issue usually appears later in service rather than during commissioning.

Common Fail-Safe Configurations

- Fail-open – Used where pressure relief or flow continuation is safer than isolation

- Fail-closed – Common where isolation prevents equipment damage or fluid release

- Fail-in-place – Applied where sudden movement introduces more risk than holding position

The valve, actuator, and control system must be evaluated together. Spring-return actuators, accumulators, and redundant control paths are common. Improper fail-safe selection can result in thermal shock, pressure excursions, or mechanical damage during upset conditions.

Why Do Valves Fail in Severe Service Applications?

- Seat erosion – High-velocity flow, entrained solids, cavitation, or flashing damage seating surfaces quickly. Leakage typically follows once contact surfaces degrade.

- Thermal distortion – Differential expansion between body, seat, and trim materials can cause binding, loss of contact pressure, or misalignment during temperature swings.

- Cavitation / flashing damage – Localized pressure collapse creates pitting and surface damage that spreads with repeated cycling. In control service, vibration often appears before visible leakage.

- Actuator fatigue / undersizing – Insufficient torque margin leads to incomplete stroke or inability to achieve shutoff. This often presents as a valve issue when the root cause is inadequate actuation over time.

Selection Factors Engineers Should Never Skip

- Process conditions – Pressure, temperature, media composition, and differential pressure must be clearly defined

- Cycle frequency – Should be based on actual operating data. A valve cycling 20x per hour behaves very differently than one cycling 20x per day

- Maintenance / testing – Rebuild access, hydrostatic testing, seat leakage testing, and functional testing under load

How does severe service valve design affect total cost of ownership?

Initial purchase cost is only one part of ownership. Downtime, maintenance labor, spare parts, and production loss often outweigh capital cost. A valve that requires frequent seat replacement can quickly exceed the cost of a higher grade design, especially in high risk units where a single unplanned shutdown may exceed the valve cost by an order of magnitude.

How Does ValvTechnologies Support Severe Service Valve Applications?

At ValvTechnologies, we design and supply severe service valves with one primary objective: long term zero-leakage performance in applications where failure is not acceptable. Our designs are built around metal-seated technology intended for high pressure, high temperature, and high cycle service.

Contact us today to speak with a valve expert about your concerns.