product

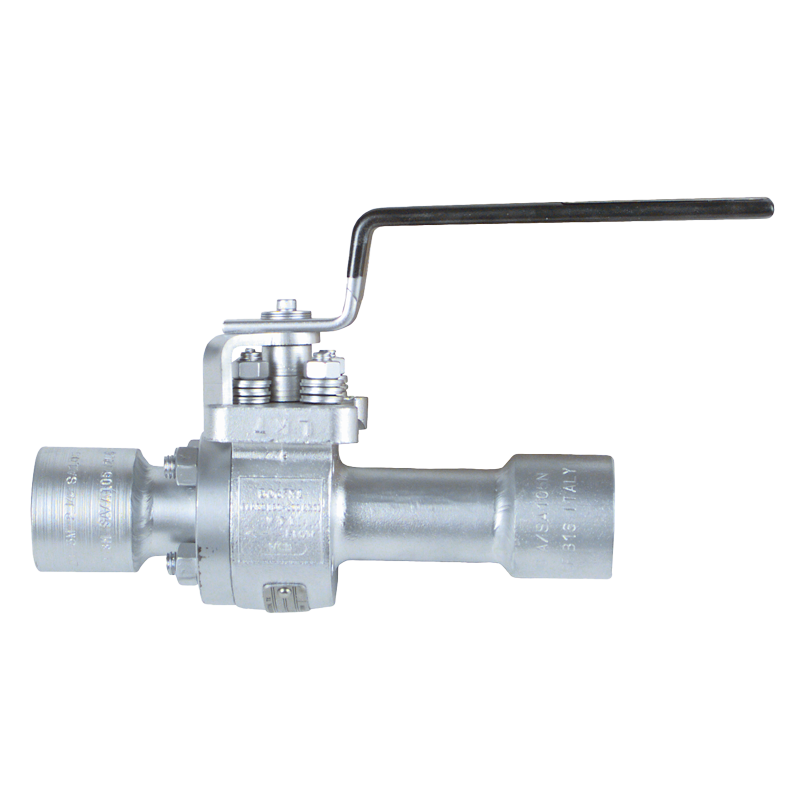

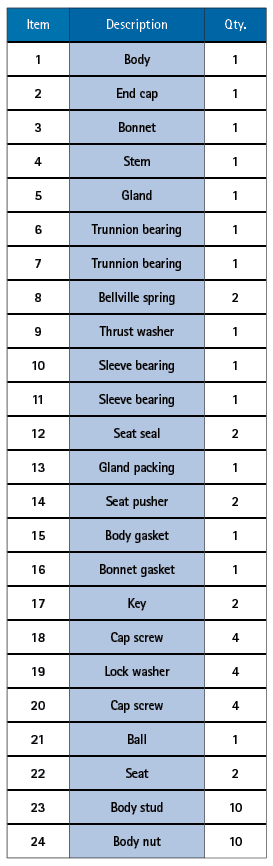

V1-3: 1/2″-2″, 150-600#

ASME / ANSI Class 150 – 600

Carbon steel (A216 WCB) – standard

Alloy steel (A217 WC9) – standard

Stainless steel (A351 CF8M) – standard

Duplex steel

Exotic alloys

Other materials available upon request

ASME B16.34

PED

Nuclear ASME III Class 1, 2 and 3

Nuclear Safety Related – 10CFR50 Appendix B

SIL

Socketweld – standard

Buttweld – standard

Other end connections available upon request

Absolute zero-leakage shutoff

- Integral metal seat. With our proprietary HVOF RiTech® coating technology, the integral seat in ValvTechnologies’ valves is resistant to the attack of abrasive magnetite and ferrous oxides that may be seen in the steam flow.

- Body seal ring. ValvTechnologies employs a field proven seal ring technology to ensure sealing under all operating conditions, up to 1400°F. The body seal ring is loaded at a pressure higher than 20,000 psi. In addition, valves sized three inch and above contain a secondary Grafoil® seal to further guarantee reliability.

- Patented coating process. The sealing surfaces are overlaid with tungsten or chromium carbide using our exclusive HVOF RiTech® process. These surfaces have a hardness of 68 – 72 Rc to allow long periods of operation in the most severe conditions.

- Live-loaded gland area. The V Series’ sealing design features a four stud, live-loaded assembly designed for heavy industrial applications. The sealing material is high purity Grafoil® surrounded by stainless steel wire mesh anti-extrusion rings. The six Belleville® springs (per stud) provide constant load pressure through extreme thermal shocks and prevent wear leaks in high-cycle service.

- Blow-out proof stem design utilizes a one piece, hard-faced, blow-out proof stem that is inserted through the inside of the body cavity eliminating the possibility of blow-out through the gland area.

- Through conduit design: No tortuous flow path. When open it has the highest possible Cv’s. Minimized wear & tear. Benefit: Eliminated vibration, reduced maintenance

- Fixed position – quarter turn: No seating torques required. Benefit: Minimized stem wear, lower cost of ownership

- Hardened blowout proof stem: One piece, inserted through the body & shouldered. Eliminates the weak link of collared & pinned designs. Benefit: Improved safety

- Metallic body seal ring: Increases body integrity by eliminating external leakage. Benefit: Improved reliability, Zero-leakage shutoff

- Live-loaded packing gland: Minimum four bolt configuration with shallow stuffing box. Ensures consistent torque at variable pressures & temperatures. Benefit: Increased reliability

- Hardcoated & mate lapped seats: High Velocity Oxygen Fuel (HVOF) RiTech® chrome carbide hardcoating with a Rockwell C of up to 72. Mate-lapped seats. Benefit: Wear & corrosion resistant, increased reliability, zero-leakage shutoff

- Seat designs: Hardcoated, both ball & integral downstream seat to the end-cap to eliminate a potential leak path. Benefit: Increased reliability

- Simplicity of design: Designed for ease of installation & maintenance. Benefit: Easily actuated, increased system reliability, increased efficiencies, ease of use, reduced maintenance

- Stringent testing: Every valve is tested, documented & serialized. Benefit: Increased reliability, increased safety, total traceability

Case Study: Teamwork Builds Success

Location: Southeast United States

Plant type: Combined Cycle Power Plant

Industry: Power

Application: HP Steam

Background: During a scheduled weekend outage, a large combine cycle power plant discovered a valve that would not move. Upon further inspection, the customer found a damaged coupler on the valve’s mounting bracket. Assuming this damaged coupler was causing the valve to lock up, the customer decided against purchasing a new valve and instead simply replaced the damaged mounting bracket. Preparing to go back online, the customer found the valve would still not function.

Requirement: Immediate shipment of a V Series metal seated ball valve for main steam draining was required to avoid extended outage time.

Result: Receiving the emergency request on Saturday, ValvTechnologies quickly assembled a cross-functional team to provide the power plant with an immediate solution. Representatives from the Shipping, Warehouse and Service departments were called to the Houston office to solve the customer’s issue. The ValvTechnologies’ team was able to identify, assemble, test and ship a replacement zero-leakage valve by the end of day Saturday, the very same day the emergency request was received.

The customer received the valve Monday morning and immediately installed it. The new valve functioned perfectly and the customer was able to go back online, saving thousands of dollars in potential down time and revenue loss.

Oval hand wheel

Actuator mounting

Lock-out device

Fossil Power Applications

- Above and below seat drains

- Ash handling

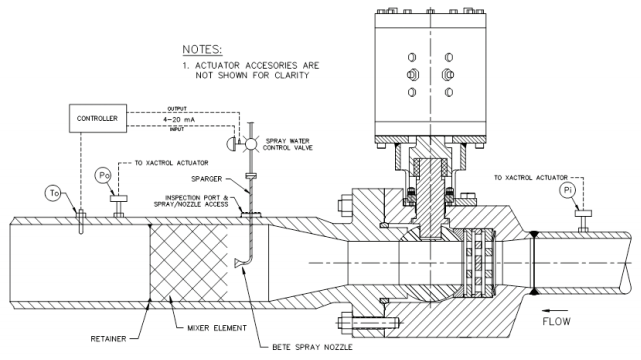

- Attemporator spray control

- Boiler drains

- Boiler feed pump isolation

- Continuous boiler blowdown

- Electronic relief

- Feedwater heater drains

- Feedwater isolation

- Instrument isolation

- Main steam stop

- Recirculation

- Seal steam regulators

- Sight/gauge glass drains

- Soot blower regulators

- Startup vents

- Steam dump

- Turbine bypass systems

- Turbine drain

Nuclear Generation Applications

- Boiler feedwater

- Circulating water system

- Component cooling

- Condensate extraction

- Condensate cooling water

- Emergency feedwater

- Fire protection system

- HP safety injection

- HP and LP heater drains

- Heat exchanger vent and drains

- Main steam system isolation, drain and vent

- Power operated relief valve (PORV)

- Pressurizer drain and vent

- Rad waste system

- Reactor coolant pump drain and vent

- Reactor head vents

- Reactor water cooling vents and drains

- Safety injection system

- Secondary system isolation, drain and vent

- Service water system isolation

- Steam generator system

- Turbine by-pass

- Turbine drain and vent

- Fukushima tie ins

- Reliable hardened vents

Upstream Oil and Gas Applications

- Wellhead choke isolation

- HIPPS

- Emergency shutdown

- Compressor recycle and isolation

- Sour gas isolation and control

- Steam, water and gas injection

- Steam chokes

- SAG-D isolation

- Pig launcher and receiver

- Mud drilling isolation and check

- Lean and rich amine isolation

- Molecular sieve regeneration isolation

- Molecular sieve absorber isolation

- First and second stage seperator isolation

Downstream and Chemical Processing Applications

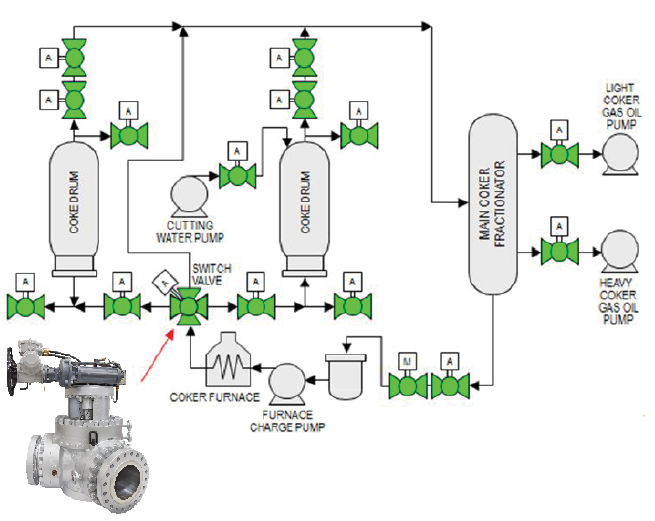

- Coking (delayed and flexi)

Switching

Feed isolation

Overhead vapor line

Cutting water isolation - Fluidized catalytic cracking

Catalyst handling

Slurry isolation and control steam - Ethylene

Steam decoke isolation

Furnace isolation

Steam vent

Quench oil isolation and control - Polyethylene

Isolation

High cycle (PTO)

Reactor block - Heavy oil upgrading and hydrocracking

(H-oil and LC fining)

Catalyst addition and withdrawal

Filter and pump isolation

Overhead vapor isolation and control

High delta-P isolation and control - Reforming (CCR)

Lockhopper

Isolation

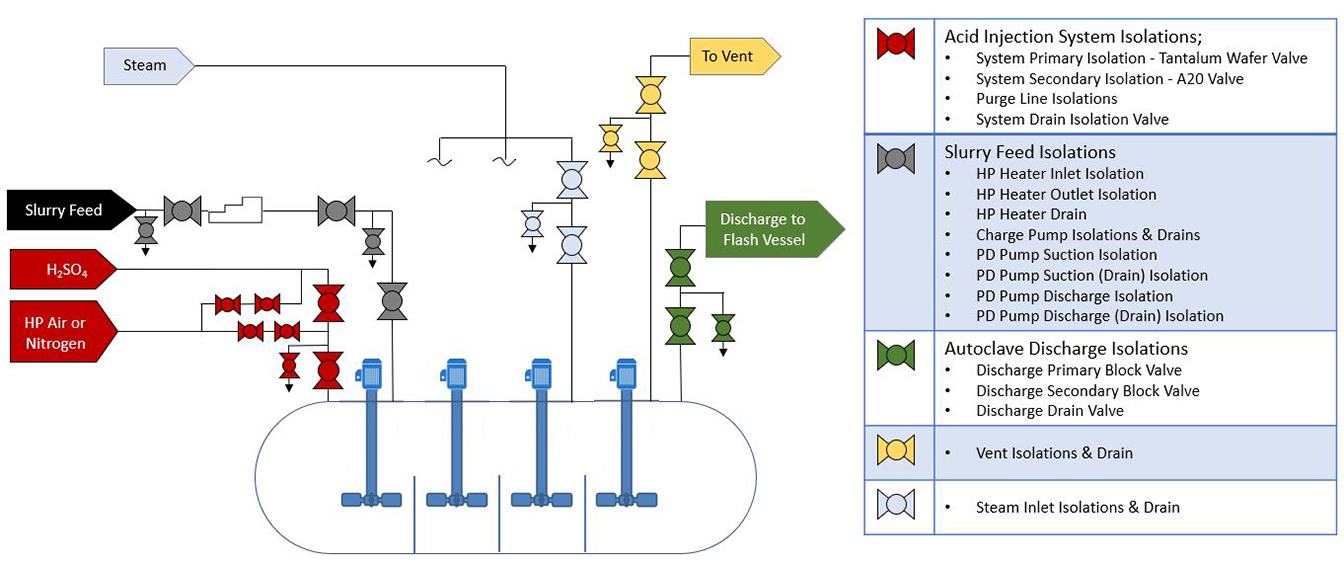

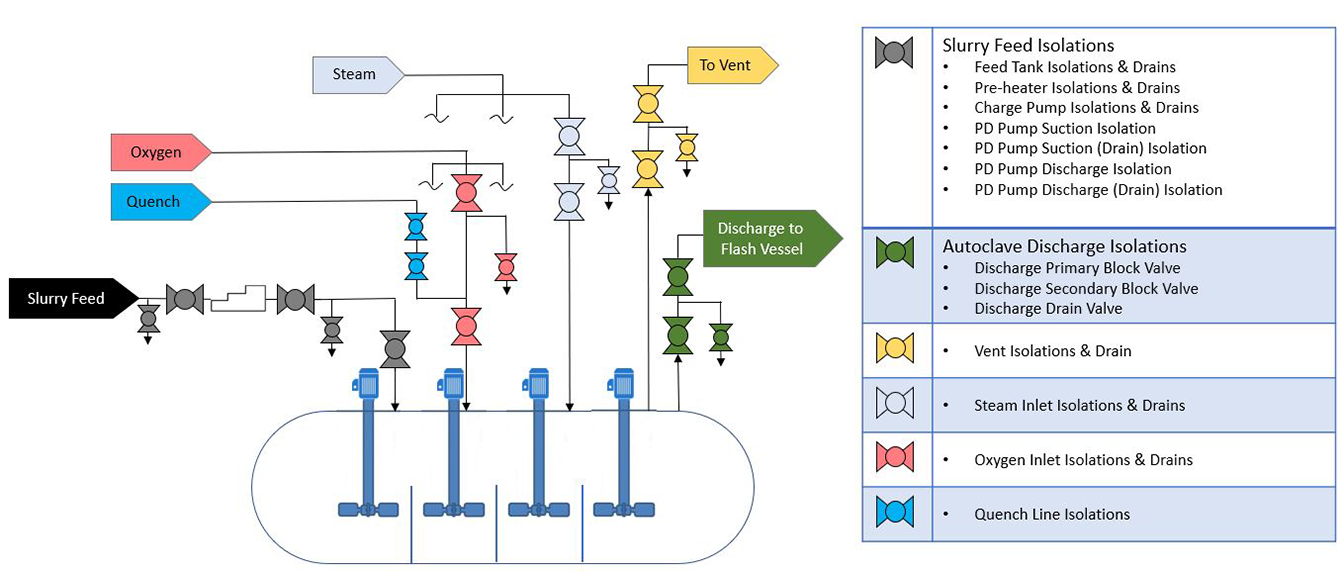

Mining and Minerals Processing Applications

- High pressure slurry

Transportation Systems

Pump discharge isolation

Pipeline isolation stations

Pipeline choke stations

Rupture disk isolation

Instrument isolation - Autoclaves

Vessel feed and discharge

Acid injection

Gas injection

Steam injection - Mineral concentrators

Thickener underflow

Discharge isolation

Filter press manifold isolation

Slurry transfer systems

PRV isolation - Waste disposal

Tailings pipelines

Paste backfill

Pulp and Paper Applications

- Boiler vent and drain

- Liquor isolation and control

- Rapid drain

- Steam isolation

- Sky vents

- Dryer pressure control

- Digester steam control

- Lime mud isolation and control

Standard ValvTechnologies’ four-year zero leakage warranty in steam and water applications.

product

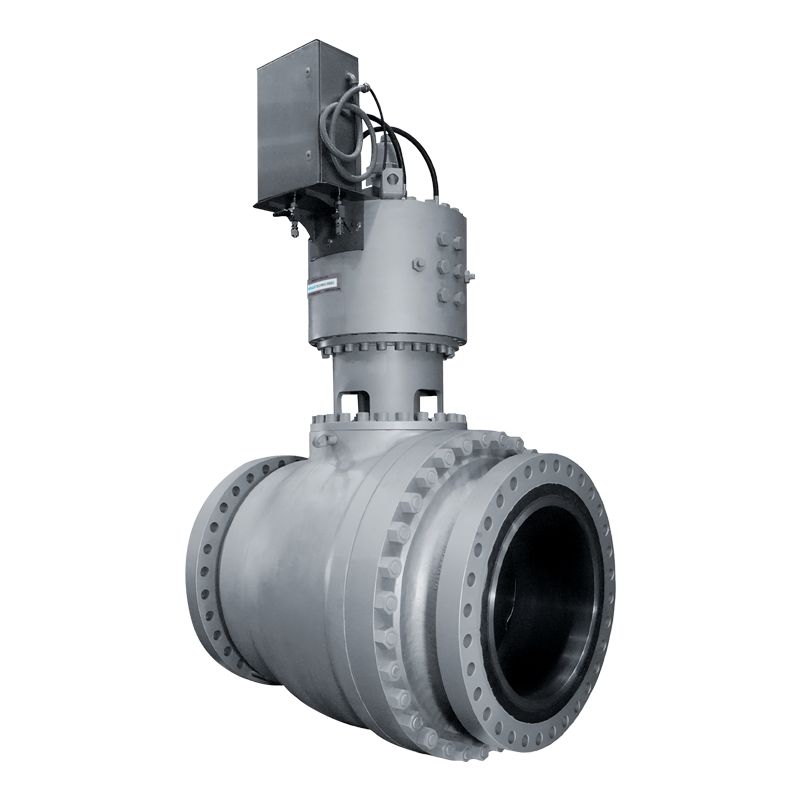

Switching Valves

product

PulseJet

ANSI/ASME 150 – 2500

- Materials (additional materials available per customer request)

- Stainless steel body and endcap

- High alloy internals

- Wear resistant coatings

- Fully metal seat

- Meets ISO-15848-1 testing requirements for fugitive emissions

- Packing requires zero adjustment or maintenance

- Capable of 500,000+ cycles

- Durable packing solution for extremely fast cycle speeds of less than 0.5 seconds

- ISO 15848-1 : 2006 Class BH

- API 607

- API 641

- ASME B16.34

- ASME B16.10

- ASME B16.5

- Raised-face or ring joint connections recommended

- Also available in butt weld connection by request

- Other connections per customer request

Exceeds endurance testing standard performed 500,000 cycles while retaining a maximum leakage rate equivalent to ISO 15848-1 2006 Class BH for the entirety of the test

- Guaranteed tight shut-off

- True metal-to-metal sealing without using secondary elastomeric seals

- Two piece, split-body design

- HVOF RiTech® coating technology

- Grafoil® seals

- Double block-and-bleed capability

- High-cycling capability

- Bi-directional sealing by design

- Single-piece anti blow-out stem design

- Impervious to high thermal cycling

- Live-load stem packing (four-bolt design)

- Stem fugitive emissions per ISO 15848-1 Class B

- Fire safe certification: API-607

- Meets ISO-15848-1 testing requirements for fugitive emissions

- Packing requires zero adjustment or maintenance

- Capable of 500,000+ cycles

- Durable packing solution for extremely fast cycle speeds of less than 0.5 seconds

These systems cycle many thousands of times per day. Conventional packing systems cannot handle the abuse of the fast cycle speed, combined with the high cycle count. ValvTechnologies’ EcoPack® solution was designed to address this challenge. The EcoPack® seal has been lab-tested at high pressure and line temperature to 450°F for over 500,000 cycles, requiring zero adjustments or maintenance. This equals longer plant operation between maintenance intervals, improved site safety and less emissions from the stem packing.

- Reduced emissions to comply with EPA fugitive emissions requirements

- Guaranteed tight shut-off. Benefit: Enhanced process safety and repeatable sealing allows operation under process excursions

- True metal-to-metal sealing without using secondary elastomeric seals. Benefit: Inherent fire safety

- Exclusive ValvTechnologies’ EcoPack® stem sealing technology. Benefit: Lower emissions and reduced maintenance

- Two piece, split-body design. Benefit: Increased safety and ease of maintenance

- HVOF RiTech® coating technology. Benefit: Extended life even in the most severe conditions, reduced maintenance costs, process reliability, enhanced process safety

- Grafoil® seals. Benefit: Reduced maintenance costs, less downtime

- Double block-and-bleed capability. Benefit: Enhanced process safety

- High-cycling capability. Benefit: Process reliability

- Bi-directional sealing by design. Benefit: Enhanced process safety, lower maintenance, less downtime

- Single-piece anti blow-out stem design. Benefit: Enhanced process safety

- Impervious to high thermal cycling. Benefit: Enhanced process safety

- Adjustment-free stem packing. Benefit: improved site safety and reduced maintenance

- Stem fugitive emissions per ISO 15848-1 Class B. Benefit: Lower emissions and enhanced process safety

- Fire safe certification: API-607. Benefit: Enhanced process safety

- Longer intervals of plant operation between maintenance schedules. Benefit: Increased safety and ease of maintenance

- Enhanced process safety and repeatable sealing. Benefit: Allows operation under process excursions

- Safer plant operation due to less exposure of plant personnel to valves requiring packing adjustment. Benefit: Increased safety

- Longer valve seal life. Benefit: Extended life even in the most severe conditions, reduced maintenance costs, process reliability, enhanced process safety

- Reductor

- Gasification of charcoal

- Gas cooling

- Phyrolysis of coal

- Combustor

- Combustion of coal/charcoal

- Melting of ash

- Discharge of ash as slag

product

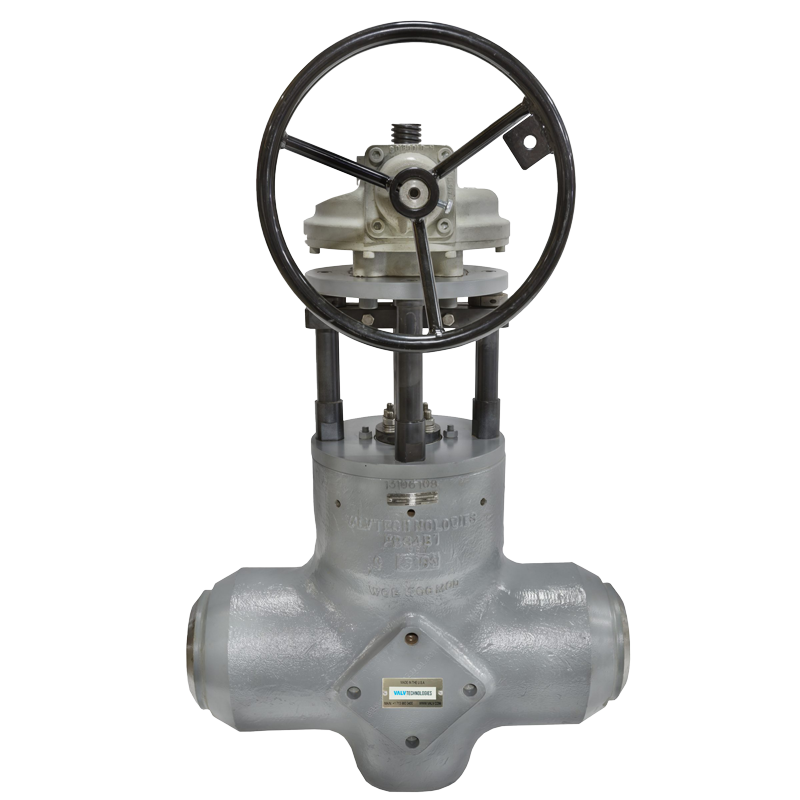

IsoTech® – Parallel Slide Gate

ASME / ANSI Class 150 – 4500

Carbon steel (A216 WCB) – standard

Alloy steel (A217 WC9, A217 C12A) – standard

Stainless steel (A351 CF8M) – standard

Duplex steel

Exotic alloys

Other materials available upon request

ASME B16.34

PED

Nuclear ASME III Class 1, 2 and 3

Nuclear Safety Related – 10CFR50 Appendix B

SIL

Buttweld – standard

Other end connections available upon request

Bi-directional, zero-leakage shutoff

IsoTech®, ValvTechnologies’ PSG valve addresses the need for true in line valve repairability in large diameter, high energy piping systems. Specifically designed for steam and feedwater applications, IsoTech® provides bi-directional, zero-leakage using our exclusive HVOF RiTech® process.

- Bonnet area. The pressure seal bonnet has been designed with a graphite composite seal. The bonnet has sufficient mechanical bolting to ensure the seal does not relax during periods when the system is not pressurized. In addition to the high reliability of the seal, the bonnet area has been designed to minimize the problems associated with maintenance on large gate valves. The valve has been designed so that the bonnet does not have to be forced in to the valve bonnet throat to allow for the segment rings to be removed. The large bolting used to ensure that the pressure seal is always loaded has also been utilized to enable simple dissassembly of the bonnet once the easy to extract segment rings have been removed.

- Gland area. The gland is the same standard design employed throughout ValvTechnologies’ various valve product lines. The stem and gland are hardfaced and polished. The packing has 316 SS woven wire mesh anti-extrusion rings top and bottom and grafoil center ring. This is combined with our proven, superior, multiple Belleville® spring stacks, live loaded stuffing box. The gland design completes the superb proven pedigree of this valve range.

- Disc and seat area. The valve discs and seats have been overlaid with the same carbide overlay (68-70 RC) as its counterpart, the ValvTechnologies’ metal seated ball valve. These seats are several magnitudes harder than Stellite 6, typically (34-38 RC) and are lapped to achieve a bubble-tight seal under all pressure conditions, including vacuum. The large spring load ensures a high initial seal, and the line pressure increases the sealing. The web guide (which is also carbide overlayed) ensures the discs are kept parallel, whether the valve is in the open or closed position. This overcomes a common gate valve problem. As the valve is cycled under differential pressure, the extremely hard surfaces continually hone and polish each other instead of scratching and galling. The seal is improved rather than degraded with wear/use.

- Back seat area. The back seat is coated with chrome carbide (typical hardness 68-70 RC) and polished to achieve a bubble tight seal.

- Fully bi-directional isolation. Benefit: outstanding operating flexibility

- Long service life – sealing surfaces are overlaid with tungsten or chromium carbide cermets using our exclusive HVOF RiTech® process. Benefit: allows for exceptional resistance to attack by abrasives and fluids

- Stem, discs and guides overlaid with tungsten or chromium carbide cermets using our exclusive HVOF RiTech® process. Benefit: extra protection delivered

- The sealing surfaces are coated with chrome-carbide hardcoating to RC 72 hardness, then diamond lapped for a precision fit. Benefit: The exceptional hardness and temperature ratings to 1800°F make our valves extremely resistant to attach of abrasives and fluids, particularly steam and flashing water

- Designed for ease of maintenance. Benefit: The only requirement is for the disc to be flat against the seat. This is easily accomplished as there are no precise angles to maintain. Pressure seal bonnet has been designed to facilitate easy removal when necessary.

- Protected seats. Benefit: In the full open position, the flow through “conduit” is positioned precisely between the seats, eliminating turbulence and flow impingements on the seats. There is no gap between our conduit and the valve seat. Small gaps in our competitors’ valves cause extreme turbulence and in come cases cavitation.

- Self-cleaning. Benefit: Frequent valve usage polishes the surface for less torque and improved sealing. The high spring load insures contact throughout the stroke of the valve and prevents particulates migrating between the disc and seat also helps assist in the honing action.

- Various flow control options, including a v-port orifice. Benefit: This is ideal for warm-up and some bypass requirements

- Stem extensions. Benefit: Because of the low break-away and running torque, various stem extensions are available so that handwheels and actuators can be located remote from the valve

- Tight shutoff. Benefit: As a standard, ValvTechnologies meets zero-leakage requirements on low-pressure air and high-pressure water

- High spring load. Benefit: ValvTechnologies’ very high spring load not only assures contact between the gate and seat, but at all positions from open to close. This allows zero-leakage on hydrogen on vacuum.

- Parallel discs. Benefit: Unlike conventional designs where the discs are only parallel in the closed position, IsoTech® valves are designed to maintain its parallel discs from both the fully-open to the fully-closed position.

- Oversized stem diameter in comparison to other PSG designs along with or in combination with the tee-slot as opposed to a threaded and pinned hanger. Benefit: Increased reliability with this durable, robust design

Case Study: Parallel Slide Gate (PSG) – Proven Success in Single Isolation

Location: England

Plant type: Coal power station

Product: PSG – Parallel Slide Gate

Background: A UK plant situated near the town of Selby, England, is the largest, cleanest and most efficient coal burning power station in the United Kingdom. Its generating capacity is 3,960 megawatts and at current output levels generates enough electricity to meet the needs of seven percent of the United Kingdom. This plant, greatly concerned about the environment, focuses on a low-carbon economy, a concept that refers to an economy which has a minimal output of greenhouse gas emissions into the biosphere, but specifically refers to the greenhouse gas, carbon dioxide (CO2). Understanding their very important role in the transition towards a low-carbon economy, this plant is committed to reducing emissions and have various projects ongoing which will deliver significant savings.

Requirement: ValvTechnologies’ UK distributor, International Procurement Limited (IPL), specialized in the supply of critical and severe service valve isolation solutions. In 2004, IPL began supplying ValvTechnologies V1-1 metal seated severe service ball valves for problem areas such as drains and bypasses for the power station. Because of the longevity and reliability of the isolation provided on the drains and by-passes, the plant began to use the ValvTechnologies products in other applications in the power station.

During 2007 and 2008, IPL supplied a number of 12, 14, 18 and 20” diameter, PSG valves for units one-three on the feed system (replace with Feed Puml and Feedwater system).

Solution: The valves proved successful in providing single isolation, which allowed maintenance to be carried out on tube leaks without shutting down the entire system. IPL has since supplied 8” and 10” diameter PSG valves to Drax Power taking the total number of units to 36. The ValvTechnologies’ zero-leakage valve range is the premier solution where isolation is required for critical and severe service applications, providing increased safety and reliability, while reducing emissions, contributing to a cleaner environment.

Case Study: ValvTechnologies’ IsoTech® PSG Valve – Reducing Total Cost of Ownership

Product: IsoTech® parallel slide gate valve

Location: Ontario, Canada

Plant type: Two-on-one combined cycle power plant

Industry: Fossil power

Application: HP steam-main steam stop

Background: The plant had two main steam isolation parallel slide gate valves (PSG’s) installed in this application. Design pressure and temperature for the application is 2350 psig at 1050°F (162 bar at 566°C). They were experiencing severe leakage when valves were required to isolate. From initial plant start-up, the frequency of valve maintenance of up to twice per year per valve. The cost of $40,000 per repair, was a particular concern for the plant. These repairs were strictly limited to disassembly, cleaning and visual inspection, grinding the seats and discs and reassembly. Well before the plant anticipated they were faced with having to replace valve seat rings and discs. The plant management decided to look at their alternatives for an upcoming outage.

Requirement: The plant installed two 12” 2500# C12A ValvTechnologies’ IsoTech® parallel slide gate valves during their spring 2014 outage. The IsoTech® valve was the perfect remedy, as it utilizes a RiTech® chrome carbide hardcoating on the disc and seats, providing a more robust, stable sealing surface at elevated temperatures.The IsoTech® valve is a through-conduit, position-seated design, which protects the valve seats from the flow stream, resulting in a valve that provides zero-leakage and requires zero-maintenance. ValvTechnologies is so confident in its ability to withstand demands of steam isolation, that they back the valve with a four-year performance warranty.

Solution: The valves have been installed and in-service for over two years and have experienced over 270 cycles with zero maintenance required. The valve’s ability to provide zero-leakage has resulted in drastically reduced downtime, which combined with the maintenance cost savings, has presented a two-year return on investment (ROI) on the original purchase/installation cost.

Drax Power Station – Heat rate efficiency and lower emissions

Severe service isolation valve leakage significantly reduces a plant’s heat rate performance, because millions of BTU’s leak away through hundreds of  valves, and never reach the turbine. With ValvTechnologies’ zero-leakage severe service isolation valves, less fuel is burned to produce megawatt’s, which leads to lower emissions ultimately lowering costs. Turbine isolation and the parallel slide gate valve.

valves, and never reach the turbine. With ValvTechnologies’ zero-leakage severe service isolation valves, less fuel is burned to produce megawatt’s, which leads to lower emissions ultimately lowering costs. Turbine isolation and the parallel slide gate valve.

Steam turbine damage by water induction is a costly economic, safety and major reliability concern. It is essential to have high quality reliable valves to isolate a turbine. ValvTechnologies’ IsoTech® parallel slide gate valve (PSG) addresses the need for true in-line repairability in large diameter, high-energy piping systems specifically designed for steam and feedwater applications.

Various bypass configurations

- Main steam isolation

- Cold reheat isolation

- LP heater isolation

- HP heater isolation

- Feedwater isolation

Delamination Guarantee + Four-Year Zero-Leakage Warranty

BACKGROUND: Delamination is the separation of the Alloy 6 or 21 hardfacing from the substrate and is believed to be caused by a sigma phase formation typically found when applied to F91 or C12A materials. This results in catastrophic destruction of the seat seal allowing the migration/liberation of the hardfacing, jeopardizing downstream components. The industry first learned of Alloy 6 delamination in a large valve designed for high-pressure/high-temperature steam service at the 2009 7F Users Group conference. 7F Users Group, Inc. is organized to provide an open forum through conferences and technological aids to the owners/operators of the GE 7F combustion turbine generator systems for effective communication, discussion and information dissemination regarding the operation, maintenance, inspection, troubleshooting and repair of such systems to maximize equipment performance and reliability

An alert concerning Alloy 6 liberation came from GE Energy, which issued Technical Information Letter 1626 on January 30, 2009. It advised steam-turbine owners to check the condition of the Alloy 6 inlay sections used in fabricating seats for the OEM’s combined stop and control valves. Guidelines and Specifications for High-Reliability Fossil Power Plants, 2nd Edition “Best Practice Guideline for Manufacturing and Construction of Grade 91 Steel Components”, was introduced in June 2015 by The Electric Power Research Institute (EPRI).

SOLUTION: ValvTechnologies’ IsoTech® parallel slide gate valves are built specifically for modern-day severe service power applications where temperatures exceed 1000˚F (538˚C). Our RiTech® 31 hardcoating technology is impervious to the effects of high temperature cycling typically seen in combined cycle power plants in main steam isolation and hot reheat applications. ValvTechnologies guarantees that our IsoTech® parallel slide gate valve, provided with our recommended RiTech® 31 hardcoating for use in high-pressure and temperature, super-critical and ultra-super critical applications, will not delaminate for 10 years or 10,000 cycles – whichever comes first.

REMEDY:In the unlikely event the RiTech® 31 hardcoating delaminates from the substrate as described above, ValvTechnologies will provide the necessary labor, supervision and tooling to replace the defective components limited to the discs (2) and seat rings (2), either in situ or in a controlled shop environment. This guarantee is in addition to our standard Four Year, Zero-Leakage warranty. ValvTechnologies makes no warranty of any kind whatsoever, expressed or implied, other than as specifically stated herein.

Standard four-year, zero-leakage warranty in steam and water applications available in addition to the ValvTechnologies’ Delamination Guarantee.

product

Slurry Valves

product

HPAL & POx Autoclave Valves

product

Electronic Relief Valve

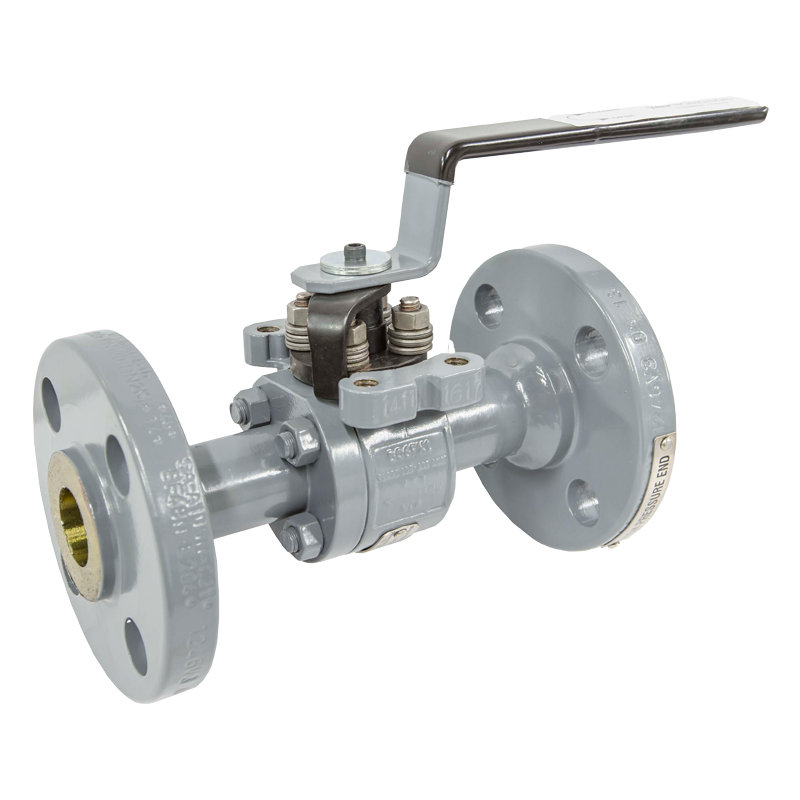

ASME / ANSI class up to 4500

Carbon steel (A105, A216 WCB) – standard

Alloy steel (F22, F91, A217 WC9, A217 C12A) – standard

Stainless steel (316H, A351 CF8M) – standard

Duplex steel exotic alloys

Other materials available upon request

ASME B16.34

PED

Nuclear ASME III Class 1, 2 and 3

Nuclear Safety Related – 10CFR50 Appendix B

SIL

Buttweld – standard

Raised-face flange – standard

Other end connections available upon request

Repeatable tight shut-off

ValvTechnologies’ ERV fulfills the need for a zero-leakage, pilot-operated relief valve. The ERV package combines ValvTechnologies’ zero-leakage isolation valve with electronic controls to monitor and regulate system pressure. Whether in a capacity relieving function requiring the ASME V-Stamp or simply an overpressure protection application, the ERV provides reliable protection for standard safety valves in many industries. ValvTechnologies can also provide an integral isolation valve, eliminating the need for costly field welding. Standard blowdown and set pressure is accurate to 1/1000.

- Integral metal seat.With our patented HVOF RiTech® coating process, the integral seat in ValvTechnologies’ rotary operating valves are resistant from the attack of abrasive magnetite or ferrous oxides in the steam flow.

- Body seal ring. ValvTechnologies employs a field proven seal ring technology to ensure sealing under all operating conditions, up to 1400°F. The body seal ring is loaded at a pressure higher than 20,000 psi. In addition, valves sized three inch and above contain a secondary Grafoil seal to further guarantee reliability

- Patented coating process. The sealing surfaces are overlaid with tungsten or chromium carbide using our exclusive HVOF RiTech® process. These surfaces have a hardness of 68 – 72 Rc to allow long periods of operation in the most severe conditions.

- Live-loaded gland area. The V Series gland packing design features a four stud, live-loaded assembly designed for heavy industrial applications. The packing material is high purity Grafoil® surrounded by carbon fiber / Inconel anti-extrusion rings. The six Bellville springs (per stud) provide constant load pressure through extreme thermal shocks and prevent wear leaks in high cycle service.

- Blow-out proof stem design utilizes a one piece, hard-faced, blow-out proof stem that is inserted through the inside of the body cavity eliminating the possibility of blow-out through the gland area.

- End cap. ValvTechnologies design utilizes a end cap with a diffuser outlet with optional end connections.

- Tight shut-off: As a standard, ValvTechnologies meets zero-leakage requirements on low-pressure air and high-pressure water

- High spring load: ValvTechnologies’ very high spring load not only assures contact between the ball and seat, but at all positions from open to close

- Accuracy to 1/10% of 1 PSI: Pinpointed opening pressure

- High-precision reliability: Consistent reliable operation

- Low maintenance requirements: Low cost-of-ownership

- Accurate blow-downs: Major cost savings

- Seat out-of-flow path when open: Unimpeded flow path with no impingement

- Easily adapted to existing controls: Potential cost-saving when adaptable to existing controls

- Various standard control packages: Highly customizable

- Integral isolation valves available: Two valves in one for easy installation

- Full pressure protection: Maximizes over pressure protection

- Easily adjusted high and low set points: Ease if installation set up

- Secondary pressure signals can be taken from the boiler nozzle or any other source – customer’s choice: Installation flexibility

- Multiple signals can be prioritized: Operational flexibility

- Standard controls can be adapted to customer requirements: Installation flexibility

- DCS signal interfaces available as dry and wet contacts: User-friendly adaptability

Z Series ERV – Premium Package ; Standard with a control box, complete fast-acting actuation package, longer diffuser discharge piping which minimizes noise and maximizes flow.

- Set points – The set points of the “Z” series ERV are ± 0.1% accuracy. This accuracy results in less steam loss during an actuation/cycle and better protection of the drum and superheat conventional safety valves.

- Safety – The take off point for the signal will typically be from the drum or superheater. This live steam point must then be cooled to prevent overheating of the pressure transmitter. To ensure safe maintenance and operations, ValvTechnologies has designed a system which consists of a coiled P22 piped siphon which is then welded to a Monel diaphragm seal. The outlet of the Monel diaphragm seal is then connected to the miniature cooling tower and the piezoresistive transmitter. As the diaphragm seal is a pressure boundary the transmitter may be removed without breaking into the pressure boundary.

- Diffuser outlet – The diffuser must be piped to a discharge drip pan for reliable and safe operation. Hard piping to a header or silencer is strictly forbidden.

- Controls – The standard control unit, in addition to lights, push buttons and selector switch, will also have a programmable controller to allow easy adjustments of blow-down. It also includes an actuation/cycle counter and a local pressure indication display.

- Optional isolation valve – Combination valve package for non-ASME Code Section I V stamped applications for two valves in one assembly eliminating a critical weld during installation. ASME Code Section I V stamped applications require a minimum of two ERVs for redundancy purposes.

R Series ERV – Economical Package – Standard product with a shorter diffuser discharge, without the fast-acting actuation package and control box. As with the Z Series, the discharge must be piped to a drip pan for safe reliable operation.

- Set point – Accurate to 0.25% with pressure transducer that customer connects to a pressure sensing line. The line requires an isolation device.

- Standard actuation – High temperature pneumatic actuator with solenoids and limit switch that contains relevant terminals

- Terminal box – for connections from the control room

- Optional – Siphon and control box

- Optional isolation valve – See explanation above

Our Promise | Absolute Zero-leakage

The ValvTechnologies ERV for use in main steam relief system is a vital contributer toward the safe and reliable operation of a power plant. It is not to be used as a start up / sky vent. Utilizing this product in that capacity voids any warranty, expressed or implied.

Seller warrants the equipment of its own manufacture to be free of defects in material and workmanship. The equipment must be installed utilizing manufacturer’s recommended installation instructions, incorporating industry guidelines, and proper use of the equipment for its intended safety function during normal plant operations, for a period of four years from date of shipment from Seller’s plant. Seller’s obligation under this warranty shall be strictly limited, at Seller’s option, to: (i) furnishing replacement parts for, or repairing without charge to Purchaser, F.O.B. Houston, Texas; or (ii) repair, without charge to Purchaser, at costs comparable to Seller’s normal manufacturing costs, those parts proven defective; or (iii) in discharge of Seller’s maximum liability herewith, refunding all monies paid by Purchaser to Seller for the product and, at discretion of Seller, having the product transportation charges relative to corrective work, defective parts or replacement parts shall be born by Purchaser. Purchaser shall give Seller immediate notice upon discovery of any defect.

The undertaking of unauthorized repairs or replacement by Purchaser or its agents or any alteration in material or design of the Seller’s product, components or parts thereof by any party other than a ValvTechnologies authorized representative shall void all obligations of Seller regarding the product and any associated warranty herein stated or implied and shall relieve Seller of all responsibility herewith.

Finished materials and accessories purchased from other manufacturers, whether attached to manufactured product of the Seller or not, are warranted only to the extent of manufacturer’s warranty to Seller. Warranty responsibility for the entire valve and actuator assembly shall be assumed by the company selecting and/or mounting an operating device on a bare stem valve. Seller has the sole discretion to determine if an automated bare stem valve shall be within Seller’s warranty obligation. Further, the full or partial removal, tampering or alteration of the actuation system, parts or components by any party other than a ValvTechnologies’ authorized representative shall void all obligations of Seller regarding the product and any associated warranty herein stated or implied.

Seller’s sole liability shall be exclusively as set forth herein, and Seller shall not be liable for any incidental or consequential damages due to its breach of any warranty herein contained, or otherwise. Without limitation to the foregoing, in no event shall Seller be liable for the loss of use of the product, or for the loss of use of any other product, process, plant, equipment, or facilities of the Purchaser or the end-user whether partially or wholly due to defects in material and/or design of Seller’s product; and in no event shall Seller be liable for removal of appurtenances or incidentals such as connections, pipe work and similar items of obstruction or for any cost brought about by the necessity of removing the product from its point of installation.

Seller makes no warranty of any kind whatsoever, express or implied, other than as specifically stated herein; and there are no warranties of merchantability and/or fitness for a particular purpose which exceed the obligations and warranties specifically stated herein.

Parts furnished without charge as replacements for original parts under warranty are warranted for that period of time during which the original parts warranty is effective.

FOUR-YEAR, ZERO-LEAKAGE GUARANTEE

product

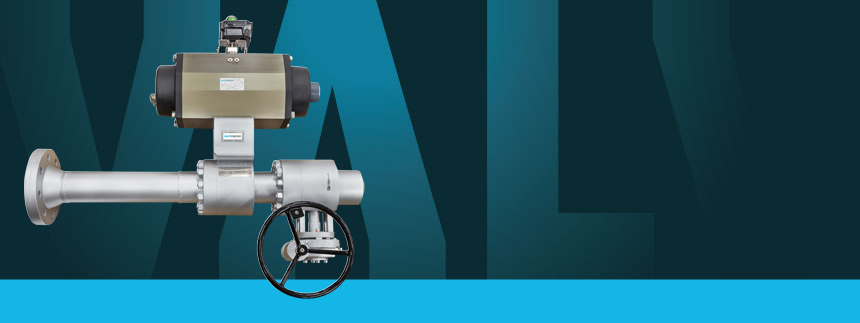

Automated Valve Packages

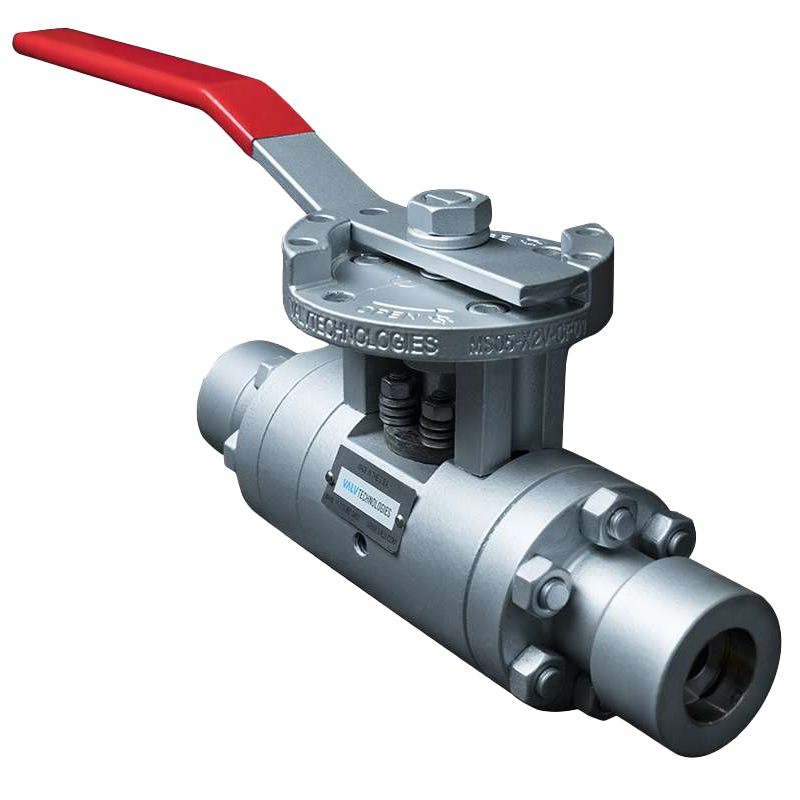

ASME / ANSI Class 900-4500

Carbon steel (A105WCB) – standard

Alloy steel (F22, F91) – standard

Stainless steel (316H) – standard

Duplex steel

Exotic alloys

Other materials available upon request

ASME B16.34

PED

Nuclear ASME III Class 1, 2 and 3

Nuclear Safety Related – 10CFR50 Appendix B

SIL

Socketweld – standard

Buttweld – standard

Other end connections available upon request

Absolute zero-leakage shutoff

- Integral Metal Seat – With patented ceramet and our exclusive HVOF RiTech® coating process, the integral seat in ValvTechnologies’ rotary operating valves are resistant to attack of abrasive magnetite or ferrous oxides in the steam flow.

- Body Seal Ring – ValvTechnologies employs a field proven seal ring technology to ensure sealing under all operating conditions, up to 1400°F (760°C). The body seal ring is loaded at a pressure higher than 20,000 psi (1379 bar).

- Patented Coating Process – The sealing surfaces are overlaid with tungsten or chromium carbide using our exclusive HVOF RiTech® coating process. These surfaces have a hardness of 68-72 Rc to allow operation in the most severe conditions.

- Blow-out Proof Stem – ValvTechnologies’ design utilizes a one piece, hard-faced, blow-out proof stem that is inserted through the inside of the body cavity eliminating the possibility of blow-out through the gland area.

- Live Loaded Gland Area – The V1-1 gland packing design features a four-stud, live-loaded assembly designed for heavy industrial applications. The packing material is high purity Grafoil® surrounded by carbon fiber/inconel anti-extrusion rings. The six Belleville springs (per stud) provide constant load pressure through extreme thermal shocks and prevent wear leaks in high-cycle service.

- Quick delivery. Benefit: Improved operational performance, decreased downtime, increased profitability

- Turnkey system. Benefit: Cost savings through inventory reduction

- Single source solution. Benefit: Supply chain optimization

- Four-year warranty*: The very best in the industry. Includes valve and actuator automation packages. Benefit: Lower cost of ownership, increased reliability

- Through conduit design: No tortuous flow path. When open it has the highest possible Cv’s. Minimized wear and tear. Benefit: Eliminated vibration, reduced maintenance

- Fixed position – quarter turn: No seating torques required. Benefit: Minimized stem wear, lower cost of ownership

- Hardened blowout proof stem: One piece, inserted through the body & shouldered. Eliminates the weak link of collared & pinned designs. Benefit: Improved safety

- Metallic body seal ring: Increases body integrity by eliminating external leakage. Benefit: Improved reliability, zero-leakage shutoff

- Live-loaded packing gland: Minimum four bolt configuration with shallow stuffing box. Ensures consistent torque at variable pressures and temperatures. Benefit: Increased reliability

- Hardcoated and mate lapped seats: High Velocity Oxygen Fuel (HVOF) RiTech® chrome carbide hardcoating with a Rockwell C of up to 72. Mate-lapped seats. Benefit: Wear and corrosion resistant, increased reliability, zero-leakage shutoff

- Seat designs: Hardcoated, both ball and integral downstream seat to the end-cap to eliminate a potential leak path. Benefit: Increased reliability

- Simplicity of design: Designed for ease of installation and maintenance. Benefit: Easily actuated, increased system reliability, increased efficiencies, ease of use, reeduced maintenance

- Stringent testing: Every valve is tested, documented & serialized. Benefit: Increased reliability, increased safety, total traceability

- *power applications

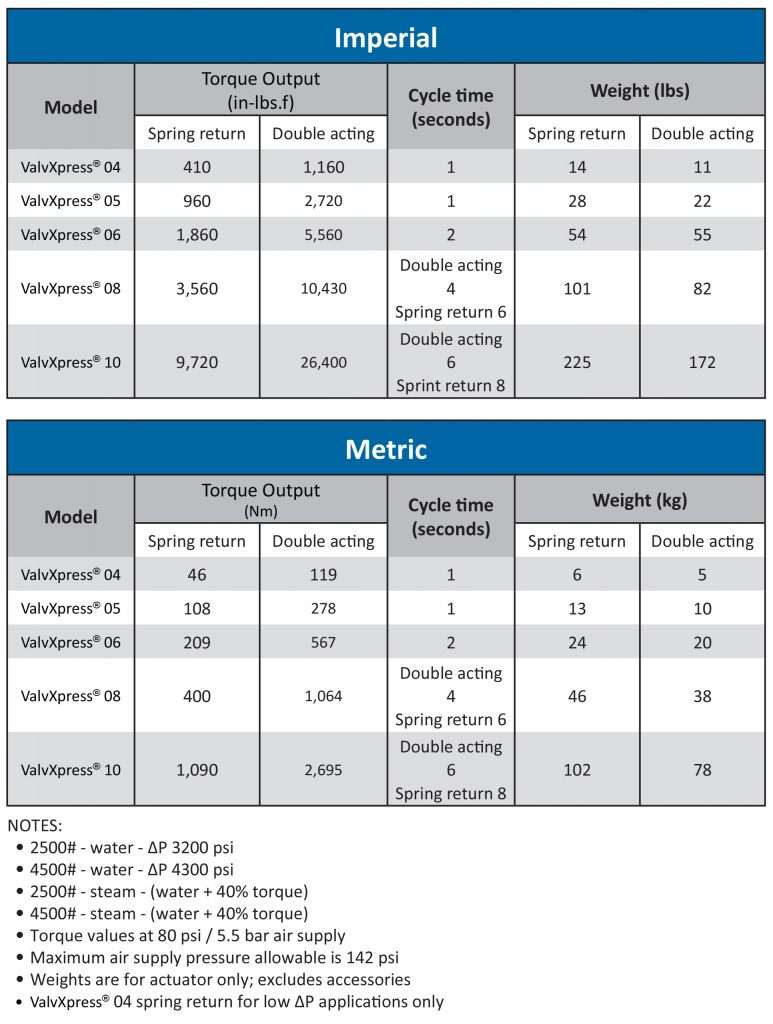

The ValvXpress® program provides customers with three different options to choose from:

- The Total Package: includes the superior quality of the V1-1 valve, integral stop mounting kit and ValvTechnologies’ actuator, backed with the best four-year guarantee in the industry (*steam and water applications).

- Build-Your-Own: ValvXpress® includes the superior quality of any ValvTechnologies’ valve, integral stop mounting kit allows customers to choose custom accessories based on their specific needs.

- Actuator-Only: Select your ValvXpress® actuator and pair it with any ValvTechnologies’ valve and integral mounting kit.

The Total Package includes:

- Complete pre-engineered V1-1 valve, mounting kit and actuator fully assembled, tested and ready to install

- Standard delivery two weeks

- Four-year warranty* on the total package

ValvXpress® Total Package benefits:

- Fastest leadtime – in time for your outage

- Quick shipment

- Fully assembled, tested, ready to install

- 100% pre-engineered for speed

Build-Your-Own ValvXpress® packages include:

- Complete valve and integral stop mounting kit

- Your choice of actuator (spring-return, double-acting or fast-acting)

- Your choice of accessories. Select from our standard accessories for us to assemble or specify your own make and model for us to assemble. Or buy your own limit switches, filter/regulators and solenoids and assemble to a plain actuator.

- Standard delivery four+ weeks

- Four-year warranty* on the total package

ValvXpress® Build-Your-Own benefits:

- Short leadtime

- Customized to meet your specific needs

- Fully assembled, tested, ready to install

- Engineered to order

Actuator-Only package includes:

- Integral stop mounting kit

- Your choice of actuator (spring-return, double-acting)

- Buy your own limit switches, filter/regulators and solenoids and assemble to a plain actuator

- Standard delivery four+ weeks

- Four-year warranty* on the total package, excluding accessories

ValvXpress® Actuator-Only benefits:

- Fully customized actuator based on your specifications

- On par with any ValvTechnologies’ valve

- Benefit from the reliability of the integral stop mounting kit

The actuators utilize a rack and pinion design which provides constant torque output in a compact package.

The actuators utilize a rack and pinion design which provides constant torque output in a compact package.

The torque output is proportional to the air supply pressure. Twin horizontally opposed cylinders incorporate piston guides to ensure engagement between the rack and pinion. Double acting and spring return models are of comparable compact design.

- Hard anodized body with high-temperature seals

- Maximum working pressure 142 psi / 10 bar

- Maximum working temperature 320°F / 160°C

- Air gap for heat dissipation

- Retainer prevents stem driving into ball

- Cast WCB top plate and bottom plate

- Single-fit actuator mounting

- Integral stop

- Drive sleeve

- While ValvXpress® is most commonly supplied as a valve, mounting kit and actuator package, ValvTechnologies realizes different customers have different needs. Depending on their specific needs, customer’s can choose between three different packages: The Total Package, Build-Your-Own, Actuator-Only. Click here to download package information.

- Insulating jackets: For further protection valves can be fitted with removable and reusable valve insulation blanket jackets.

- Mounting hardware: ValvTechnologies’ external stop mounting hardware minimizes or eliminates stem and sealing performance problems caused by a faulty re-installation of an operator on an automated valve.

- Zero-leakage bi-directional sealing upgrade: ValvTechnologies’ available upgrade provides the user with superior back pressure protected sealing capability and is designed to prevent the upstream load spring from collapsing in a reverse flow or back pressure condition: in this design, however, Class V shutoff in the reverse direction is guaranteed during an upset condition.

- Other options:

- Special end connections available

- Class V sealing in the reverse direction

- Tandem arrangements

- Complete automation packages available

- Characterized trim

- Oval hand wheel

- Actuator mounting

Four-year guarantee on valve and actuator automation packages.

product

Turbine Bypass Systems

ASME / ANSI Class 150 – 4500

Carbon steel (A105, A216 WCB) – standard

Alloy steel (F22, F91, A217 WC9, A217 C12A) – standard

Stainless steel (316H, A351 CF8M) – standard

Duplex steel

Exotic alloys

Other materials available upon request

B16.34 PED N & NPT – Nuclear Authorized

Buttweld – standard

Raised-face flange – standard

Other end connections available upon request

Zero-leakage

- Operation at turndown conditions far below levels that can be achieved with standard governor systems

- Guaranteed zero-leakage performance delivers repeatable isolation and preserves operating integrity

- Outstanding control in critical combined cycle operation improves system efficiency and productivity

- Assured drum level control stability during a trip event and faster stream turbine re-starts via improved control system

- High-quality performance created by experienced design and ISO 9001-certified manufacturing

Various control packages available integral isolation