Atmospheric Distillation – Application Overview

Atmospheric (crude) distillation is the first major process in a refinery. Crude oil passes through the atmospheric topping unit on the way to be further processed. Typically, the feed enters the distillation column at around 350-390°C (660-730°F). Vapors rise to the top of the column and heavier liquid hydrocarbons fall to the bottom. Hydrocarbon fractions are withdrawn from the tower according to their specific boiling temperatures.

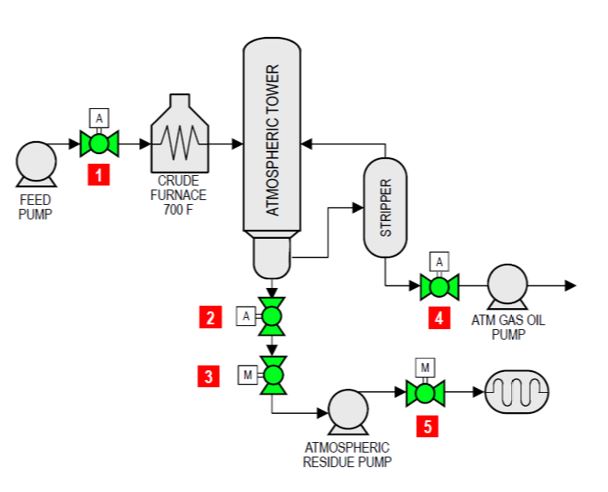

In a crude distillation process, there are valves controlling the flow of the feed into the furnaces. The fuel input is also on flow control. The distillation towers have valves controlling the flow of product, reflux and stripping steam. Finally, the bottoms of the towers have valves ensuring safe operation of the pump.

PROCESS OBJECTIVE

To distill and separate valuable distillates (naphtha, kerosene, diesel) and atmospheric gas oil (AGO) from the crude feedstock.

PRIMARY PROCESS TECHNIQUE

Complex distillation

| FLOW DIAGRAM | |||||

|

|||||

| Item | Applications | Temp range (°F) | Pressure (psi) | Size (in) | |

| 1 | Feed isolation | 200 – 320 | 100 – 200 | 6 -10 | |

| 2 | Atmospheric bottoms emergency block valve | 300 – 450 | 20 | 4 – 8 | |

| 3 | Atmospheric bottoms pump isolation | 300 – 450 | 20 | 8 – 14 | |

| 4 | Atmospheric gas oil stripper emergency block valve | 300 – 450 | 20 | 6 – 10 | |

| 5 | Atmospheric bottoms exchanger isolation | 300 – 450 | 150 | 6 – 10 | |

| 6 | Heater outlets isolation | 500 – 600 |

150 | 6 – 10 | |