Improve up-time. Decrease production losses.

ValvTechnologies’ four way switch valve design focuses on operational reliability, extended mean time before major repair and low cost of total ownership.

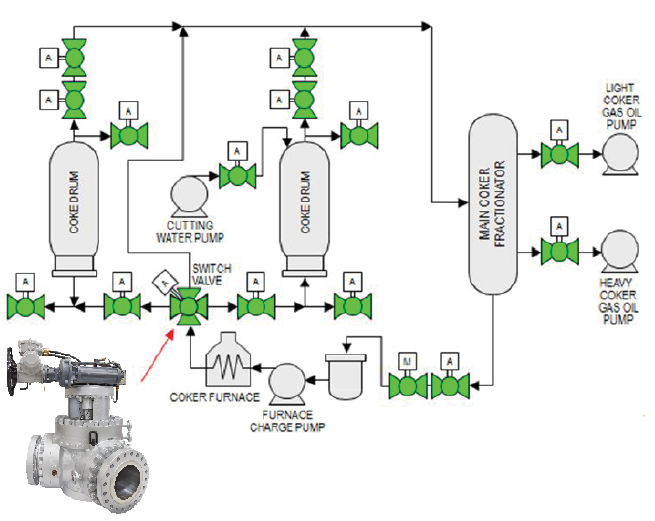

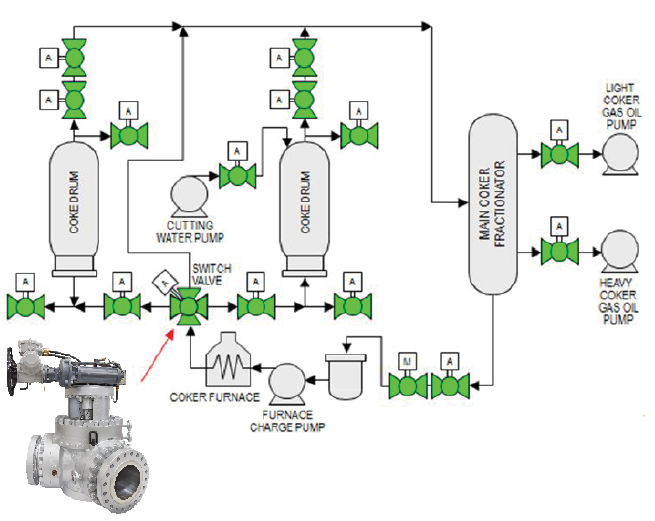

The delayed coker process is a batch process, one of the most hostile environments in the refinery – due to the abrasive / erosive, properties of the coke by-product and high temperature reactions. Valves are cycled frequently and failure can lead to a complete shutdown of a unit, resulting in large process and financial costs. Optimizing valve life-cycle is critical to operational efficiency.

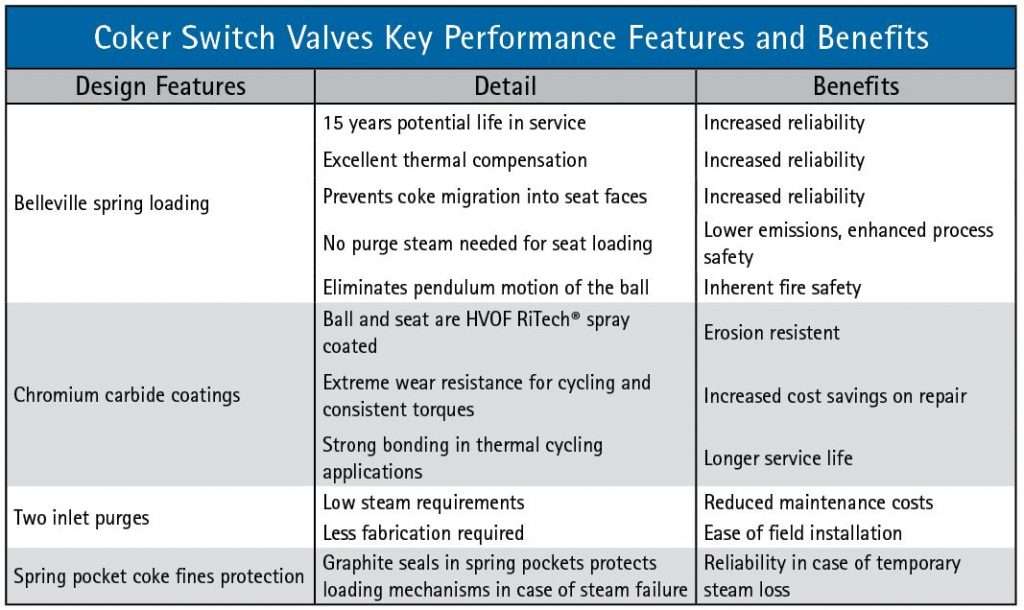

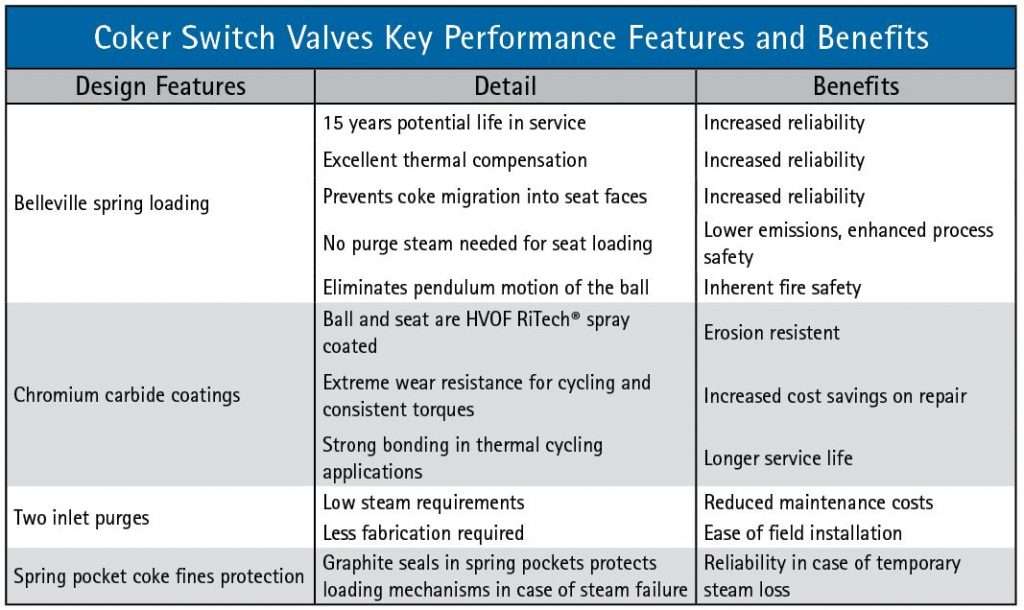

- 15 years potential life in service. Benefit: increased reliability

- Excellent thermal compensation. Benefit: increased reliability

- Prevents coke migration into seat faces. Benefit: increased reliability

- No purge steam needed for seat loading. Benefit: Lower emissions, enhanced process safety

- Eliminates pendulum motion of the ball. Benefit: inherent fire safety

- Ball and seat are HVOF RiTech® spray coated. . Benefit: erosion resistant

- Extreme wear resistance for cycling and consistent torques. Benefit: Increased cost-savings on repair

- Strong bonding in thermal cycling applications. Benefit: longer service life

- Low steam requirements. Benefit: reduced maintenance costs

- Less fabrication required. Benefit: longer service life

- Graphite seals in spring pockets protects loading mechanisms in case of steam failure. Benefit: reliability in case of temporary steam loss

Extended flange connections available

Remote start – stop button control panels