Engineered for Precision.

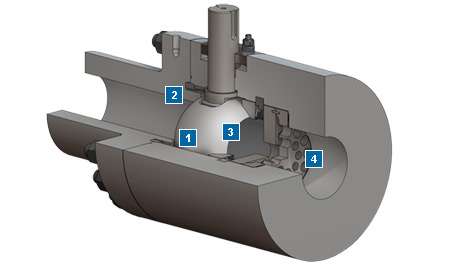

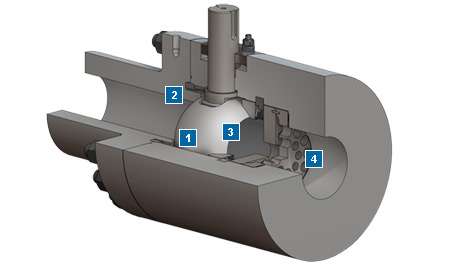

In addition to normal flow conditions, the Xactrol® Mark II has a second flow port through the ball which is designed to handle continuous minimum flow conditions. For minimum flow conditions, with the valve in the closed position, the cross-hole through the ball determines the minimum flow condition.

- Integral Metal Seat. With our exclusive HVOF RiTech® coating process, the integral seat in ValvTechnologies’ rotary operating valves are resistant from the attack of abrasive magnetite or ferrous oxides in the steam flow.

- Body Seal Ring. ValvTechnologies employs a field proven seal ring technology to ensure sealing under all operating conditions, up to 1400°F. The body seal ring is loaded at a pressure higher than 20,000 psi. In addition, valves sized 3″ and above contain a secondary Grafoil seal to further guarantee reliability

- Patented Coating Process. The sealing surfaces are overlaid with tungsten or chromium carbide using our exclusive HVOF RiTech® process. These surfaces have a hardness of 68 – 72 Rc to allow long periods of operation in the most severe conditions.

- The Xactrol® product group unites ValvTechnologies’ zero-leakage technology with special designs that allow rotary modulating control. From the Mark I’s design that features a characterized upstream seat to the Mark III’s precision engineered stacked disks, the Xactrol® allows the customer to combine precise flow control with tight shut-off. The Xactrol® is typically used in applications where minimum flow and relatively high differential pressures are required.

- Superior failure resistance and reliability. Benefit: Enhanced process safety

- Constant packing load maintained with four-stud, live-loaded packing assembly. Benefit: Increased safety, enhanced process efficiency, environmentally friendly

- Custom-engineered. Benefit: Process optimization

- Consistent flow-rates. Benefit: Reduced fluid costs

- Control trim made from extremely hard components. Benefit: Reduced wear, increased life of the valve

- Resistance to small entrained solids. Benefit: Lower maintenance costs, increased reliabilit

Mark II Design

- Designed for minimum/normal flow control conditions

- Variety of characterized upstream seats available

- Engineered to meet your control needs

- Includes a second flow port designed to handle continuous minimum flow conditions

Applications

The Mark II is designed for high-pressure and/or erosive services with the addition of a required

continuous minimum flow. The valve features an additional flow port through the ball for

continuous flow applications. Applications include: boiler drum and continuous blow down valves.

Trim Available:

- Mark I – single stage pressure drop

- Mark II – single stage pressure drop, continuous blowdown

- Mark III – multi-stage pressure drop

Actuator mounting