ValvXpress® – for customers who demand quick delivery of a zero-leakage automated valve solution for severe service water and steam applications. The package includes the superior quality of the V1-1 valve and ValvTechnologies’ actuator, backed with the best four-year guarantee in the industry. ValvXpress® pre-engineered, automated packages are compact, robust and ready to ship.

Pre-engineered package includes:

- 1/2″ – 4” metal-seated V1-1 ball valve

- Socket weld and butt weld end connections

- A105, F22, F91 body materials

- 2500#-4500# pressure classes

- Valve operating conditions to 1400°F (760°C)

- High-cycle pneumatic rack and pinion actuator

- Hard anodized coating

- High-temperature Viton® seals

- High-cycle mounting hardware

- Limit switch with position indicator – 2-SPDT, quick set cam, IP67, NEMA 4/4X

- NAMUR solenoid – 110V/120V, 230V, 24VDC coils

- Filter/regulator with gauge

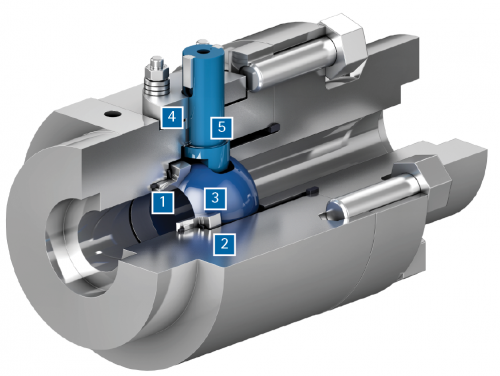

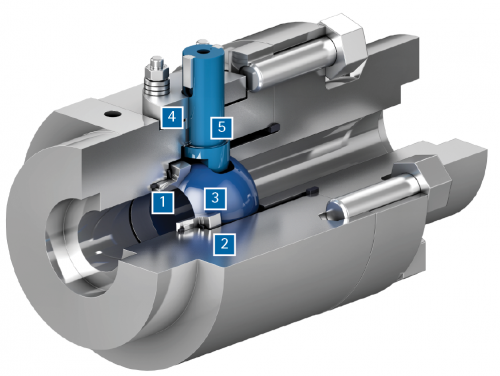

- Retainer prevents stem driving into ball

- Integral metal seat.. With our patented HVOF RiTech® coating process, the integral seat in ValvTechnologies’ rotary operating valves are resistant from the attack of abrasive magnetite or ferrous oxides in the steam flow.

- Body seal ring. ValvTechnologies employs a field proven seal ring technology to ensure sealing under all operating conditions, up to 1400°F. The body seal ring is loaded at a pressure higher than 20,000 psi. In addition, valves sized three inch and above contain a secondary Grafoil seal to further guarantee reliability

- Patented coating process. The sealing surfaces are overlaid with tungsten or chromium carbide using our exclusive HVOF RiTech® process. These surfaces have a hardness of 68 – 72 Rc to allow long periods of operation in the most severe conditions.

- Live-loaded gland area. The V Series gland packing design features a four stud, live-loaded assembly designed for heavy industrial applications. The packing material is high purity Grafoil® surrounded by carbon fiber / Inconel anti-extrusion rings. The six Bellville springs (per stud) provide constant load pressure through extreme thermal shocks and prevent wear leaks in high cycle service.

- Blow-out proof stem design utilizes a one piece, hard-faced, blow-out proof stem that is inserted through the inside of the body cavity eliminating the possibility of blow-out through the gland area.

- Zero-leakage backpressure protected bi-directional sealing. This superior back pressure protected sealing capability comes standard with the V1-1 Series valve. ValvTechnologies’ standard design prevents the upstream load spring from collapsing in a reverse flow condition. The design protects the internals from damage after an upset condition and guarantees shutoff in the reverse direction.

- Zero-leakage shutoff. Shutoff is absolute zero-leakage, exceeding the requirements of ANSI/FCI 70-2, ANSI B16.34 and API 598.

Visit www.presentation.valv.com for more information.

- Through conduit design: No tortuous flow path. When open it has the highest possible Cv’s. Minimized wear & tear. Benefit: Eliminated vibration, reduced maintenance

- Fixed position – quarter turn: No seating torques required. Benefit: Minimized stem wear, lower cost of ownership

- Hardened blowout proof stem: One piece, inserted through the body & shouldered. Eliminates the weak link of collared & pinned designs. Benefit: Improved safety

- Metallic body seal ring: Increases body integrity by eliminating external leakage. Benefit: Improved reliability, Zero-leakage shutoff

- Live-loaded packing gland: Minimum four bolt configuration with shallow stuffing box. Ensures consistent torque at variable pressures & temperatures. Benefit: Increased reliability

- Hardcoated & mate lapped seats: High Velocity Oxygen Fuel (HVOF) RiTech™ chrome carbide hardcoating with a Rockwell C of up to 72. Mate-lapped seats. Benefit: Wear & corrosion resistant, increased reliability, Zero-leakage shutoff

- Seat designs: Hardcoated, both ball & integral downstream seat to the end-cap to eliminate a potential leak path. Benefit: Increased reliability

- Simplicity of design: Designed for ease of installation & maintenance. Benefit: Easily actuated, increased system reliability, increased efficiencies, ease of use, reeduced maintenance

- Stringent testing: Every valve is tested, documented & serialized. Benefit: Increased reliability, increased safety, total traceability

- Four-year warranty*: The very best in the industry. Includes internal seat leakage & external leakage through the packing &/or body seal. Benefit: Lower cost of ownership, increased reliability

*power applications

While ValvXpress® is most commonly supplied as a valve, mounting kit and actuator package, ValvTechnologies realizes different customers have different needs. Depending on their specific needs, customer’s can choose between three different packages:

- The Total Package

- Build-Your-Own

- Actuator Only

The Total Package: This package includes the superior quality of the V1-1 valve, integral stop mounting kit and ValvTechnologies’ actuator, backed with the best four-year guarantee in the industry.

The Total Package package includes:

- Complete pre-engineered V1-1 valve, mounting kit and actuator fully assembled, tested and ready to install

- Standard delivery two weeks

- Four-year warranty* on the total package

ValvXpress® Total Package Benefits

- Fastest leadtime – in time for your outage

- Quick shipment

- Fully assembled, tested, ready to install

- 100% pre-engineered for speed

Build-Your-Own: This package includes the superior quality of any ValvTechnologies’ valve, integral stop mounting kit allows customers to choose custom accessories based on their specific needs.

Build-Your-Own package includes:

- Complete valve and integral stop mounting kit

- Your choice of actuator (spring-return, double-acting or fast-acting)

- Your choice of accessories. Select from our standard accessories for us to assemble or specify your own make and model for us to assemble. Or buy your own limit switches, filter/regulators and solenoids and assemble to a plain actuator.

- Standard delivery four+ weeks

- Four-year warranty* on the total package

ValvXpress® Build-Your-Own Benefits

- Short leadtime

- Customized to meet your specific needs

- Fully assembled, tested, ready to install

- Engineered-to-order

Actuator-Only: Select your ValvXpress® actuator and pair it with any ValvTechnologies’ valve and integral mounting kit.

Actuator-Only package includes:

- Integral stop mounting kit

- Your choice of actuator (spring-return, double-acting)

- Buy your own limit switches, filter/regulators and solenoids and assemble to a plain actuator

- Standard delivery four+ weeks

- Four-year warranty* on the total package, excluding accessories

ValvXpress® Actuator-Only Benefits

- Fully customized actuator based on your specifications

- Pair with any ValvTechnologies’ valve

- Benefit from the reliability of the integral stop mounting kit

Four-year guarantee on valve and actuator automation packages.